Impressive Info About How To Build A Wind Turbine Blade

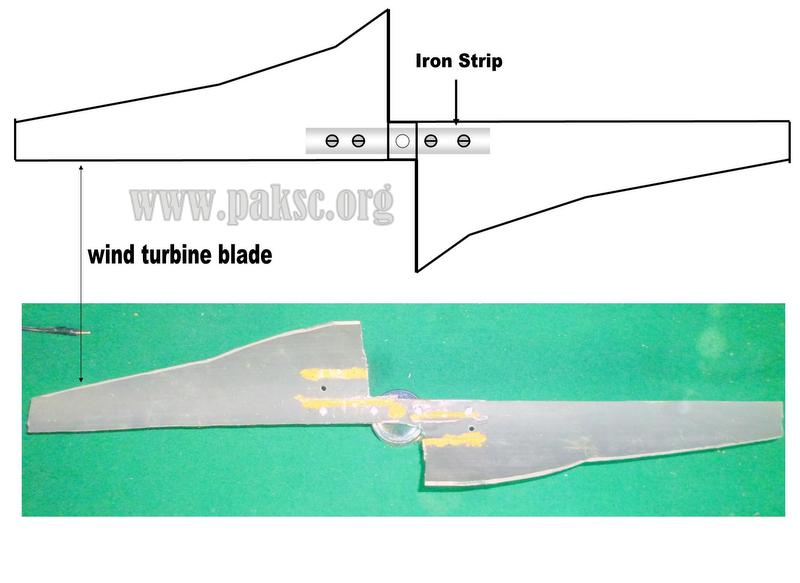

For three or more individual blades, a centre hub needs to be created onto which the wind turbine blades can be attached.

How to build a wind turbine blade. I will make this easy. Printing the airfoil templates (on paper). You can either screw or bolt the rotor blades to a hub.

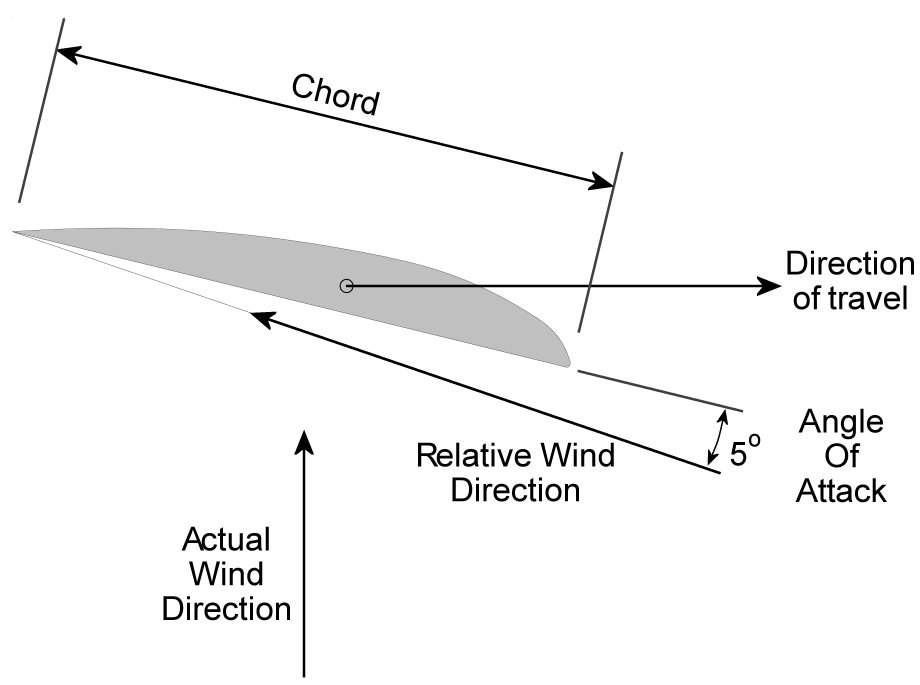

Engineers strive to design blades that extract as much. This method of carving blades and using a plywood hub c. In this video i show you how to make your own wood wind turbine blades that cost less then 2 dollars.

Carefully poke the dress pin through the center of the hub that connects the three turbine blades together. Depending upon the use of the electricity produced. But in the past several years, energy companies have sought ways to.

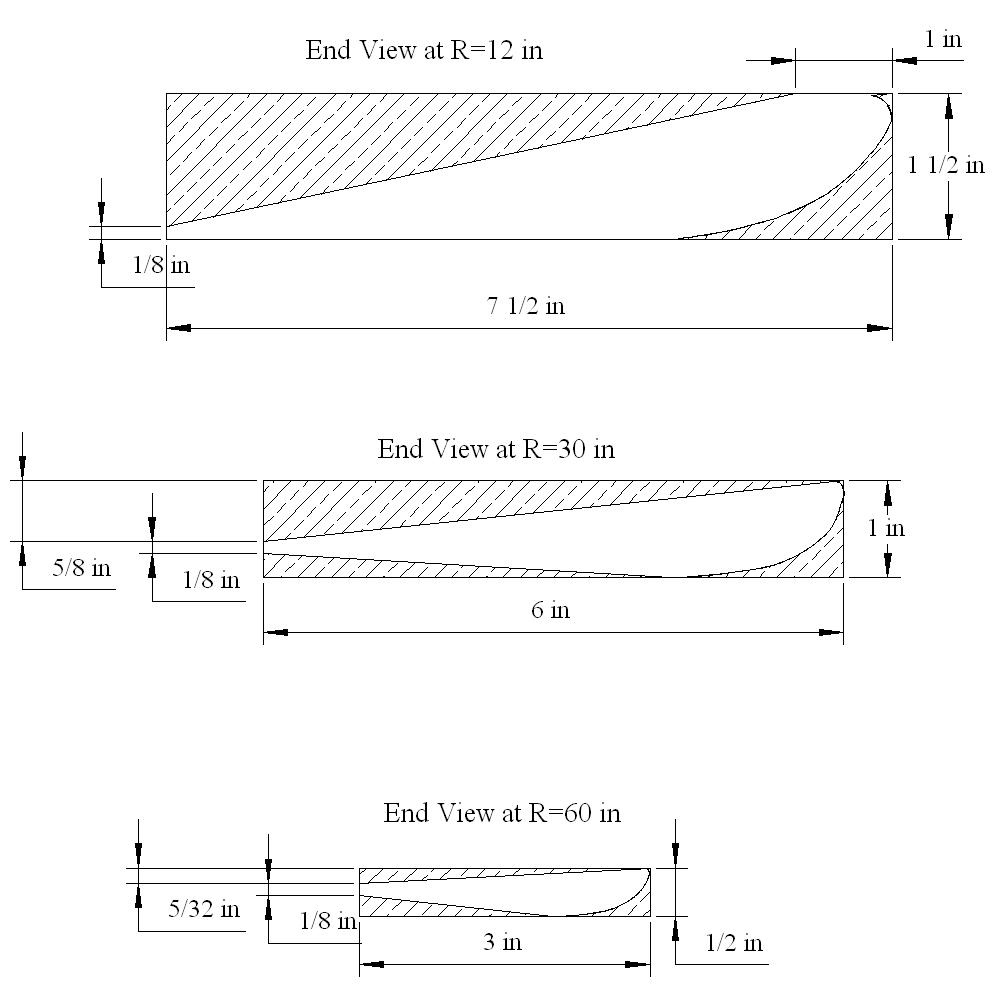

Tools and materials you need. A perforated release foil and. Wind turbine blade length or wind turbine blades size usually ranges from 18 to 107 meters (59 to 351 feet) long.

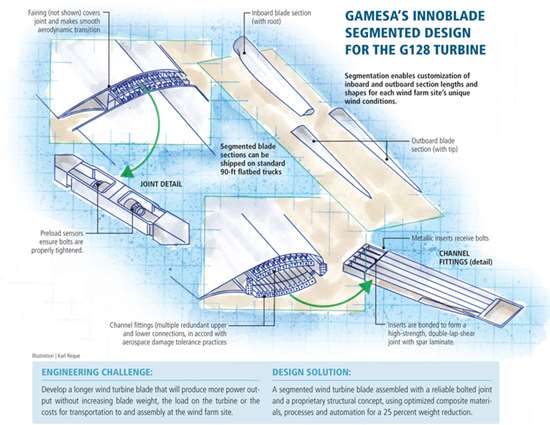

Small wind turbine blade (6 foot dia.) step 1: Structural repair of a single wind blade can cost up to $30 000 and a new blade costs on average about $200 000. Blade engineering and design is one of the most complicated and important aspects of modern wind turbine technology.

More fabric is placed on top to prepare for molding. Each mold is shaped like one half of the turbine blade and will each make up a face of the blade.